|

||||||

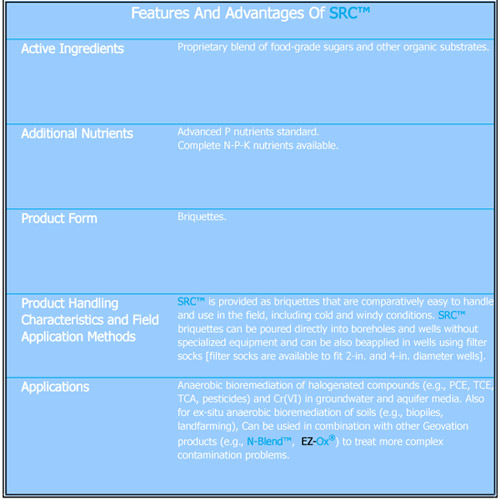

| SRC™ briquettes are easy to handle and apply in the field using filter socks for 2-in. and 4-in. wells or by direct application to wells. | ||||||

|

||||||

|

Many of the benefits of

SRC™ – in liquid form!

Granular powder is mixed into an injectable solution for more aggressive early-stage bioremediation. |

||||||

|

SRC-7™ is a patented technology comprised of a blend of carbohydrates and biopolymer substrates of varying molecular weights and solubilities. SRC-7™ is applied as solid briquettes which are poured directly into PVC treatment wells/points by gravity from the bottom up to within a few feet of the water table. SRC-7™ socks are installed immediately below and/or across the water table to target treatment of water-table smear zone and "vapor halo" CVOCs. SRC-7™ socks also consume oxygen and minimize DO near the water table to optimize treatment conditions. SRC-7™ socks can also be used for in-well treatment and monitoring. SRC-7™ briquettes disintegrate and hydrate to form a dense and concentrated substrate/nutrient slurry which promotes a relatively rapid diffusive flux and density-driven dispersion of substrates into and through aquifer media (which mimics the migration of DNAPL contaminants). SRC-7™ is an effective means of treating DNAPL source areas and high levels of sorbed-phase CVOCs. SRC-7™ is a blend of substrates (not a single compound) that stimulates robust microbial growth and diverse consortia of anaerobic microorganisms including Archaea, Bacteria, and Fungi. Microbial diversity provides a wider array of catabolic processes and metabolic functions to create a sustainable microbial ecosystem that avoids "stalled" bioremediation. Both reductive dechlorination and anaerobic oxidation processes act to degrade both parent and daughter compounds. SRC-7™ technology provides cost-effective means for the long term treatment of CVOC source areas, semi-passive bioremediation programs and "maintainable" anaerobic barriers. |

||||||